Trusted company that deals in quality-made products

Anti Corrosive Coating

450 INR/Liter

Product Details:

X

Anti Corrosive Coating Price And Quantity

- 450 INR/Liter

- 20 Liter

Anti Corrosive Coating Trade Information

- 1 Liter Per Week

- 1 Week

Product Description

Our firm counted as one of the eminent service provider in serving a superior array of Anti Corrosive Coating Services. These are rendered with a help of latest devices and adroit professionals who are master in these field. These are used to give a protective layer and make elegant finish to the required products. Coating Paint Services are made with a superlative material to give a quick drying and no lumps while coating the big space of structures.

Features & benefits :

- Wide Usage : Compatibility with most structural metals

- High Performance : Long lasting corrosion protection.

- Green Chemistry : Chromate-free coatings comply with environmental, health, and safety standards.

- Smart Functionality : System capable of repairing itself when damages.

- Cost Savings : Less maintenance, materials and labor

- Improved Productivity : May require less physical preparation of the metal surface.

We Deal In :

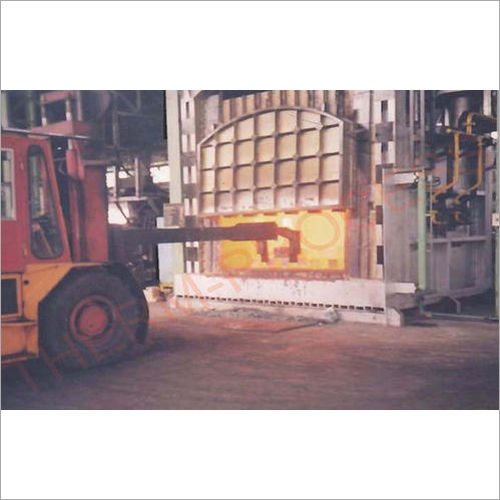

- Heat Resistant & Thermal Insulation Coating

- Corrosion Resistant Coating

- Fire Retardant Coating

- Heat & Chemical Resistant

- LPG Bullet Tank Coating

- Cold Insulation Coating

- Hot Insulation Coating

- Waterproofing coating

- Anti-Bacterial Paints

- Deep-Cleaning Service & Products

Specification :

|

Pack Size |

10 Litre, 20 Litre |

|

Application |

Industrial Use |

|

Packaging Type |

Drum |

Reliable Corrosion Protection

Shield your industrial and commercial assets with our advanced Anti Corrosive Coating. Formulated for smooth, even application, it provides a robust barrier against water and chemical intrusion, prolonging substrate lifespan. Ideal for use on metal and concrete, it ensures long-lasting performance with minimal maintenance.

Easy Application Versatility

The single-component formula is user-friendly, making it suitable for brush, roller, or spray application. This flexibility allows seamless adaptation to various surfaces and project sizes, reducing labor time and increasing efficiency. Whether for large-scale industrial structures or commercial facilities, this coating fits diverse operational needs.

FAQs of Anti Corrosive Coating:

Q: How should the Anti Corrosive Coating be applied for optimal results?

A: For best performance, ensure the surface is clean and dry before application. The coating can be applied by brush, roller, or spray, achieving a thickness of 50100 microns. Allow 1530 minutes for drying between coats and a full 24 hours for complete curing.Q: What surfaces are suitable for the Anti Corrosive Coating?

A: This coating is engineered for application on both metal and concrete surfaces, providing durable protection in industrial and commercial settings.Q: When is the best time to use this coating and how long does it last?

A: Apply the coating within its 12-month shelf life for optimal efficacy. It is suitable for projects requiring rapid drying (1530 minutes) with full cure in 24 hours, enabling efficient scheduling and project turnaround.Q: Where should the Anti Corrosive Coating be stored?

A: Store the product in a cool, dry environment away from direct sunlight and moisture. This ensures the integrity and performance of the coating during its shelf life.Q: What are the benefits of choosing this anti-corrosive coating?

A: Users benefit from excellent adhesion, low VOC emissions, water resistance, and temperature durability up to 120C. These features help prolong asset life and reduce maintenance costs.Q: Is the coating environmentally friendly and safe for use?

A: Yes, the coating is formulated with low VOC content, making it safer for installers and more environmentally responsible compared to traditional alternatives.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email