Chemical Resistant Coatings

Product Details:

Chemical Resistant Coatings Price And Quantity

- 100 Liter

- 550 INR/Liter

Chemical Resistant Coatings Trade Information

- 100 Liter Per Month

- 7 Days

Product Description

UNIVOLEN HIGH CHEMICAL RESISTANT COATING

This type of coatings cures due to chemical reaction between base and hardener. Here the hardener is added just before application of the coating. Only required quantity of the paint base should be mixed with hardener and applied immediately. The mixing ratio of base to hardener differs with type of medium and is usually defined by manufacturer of the coating. These coatings can be made with 100 % solid content and solvent free as per requirement.

These coatings are specially prepared to protect the surface from chemical attack. Here it is important that we should take proper information about the chemicals being used and the chemical fumes in nearby atmosphere before suggesting the product. We have products suitable for all mild chemicals. The details of this coating will come in relevant products section later.

DESCRIPTION:

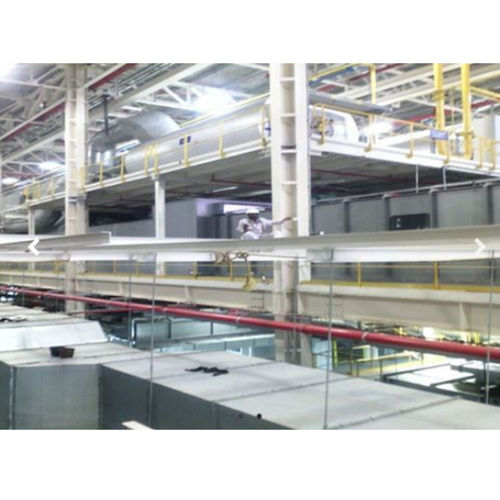

1) Our organization offers a wide range of Chemical Resistant Paints, which finds extensive application in Chemical industry.

2) These have excellent chemical resistance properties as our range is formulated using quality ingredients.

3) UNIVOLEN High Chemical Resistant Coatings is a high functionality, two component thermoset polymer coating. When cured, the UNIVOLEN High Chemical Resistant Coatings high cross-link density is unlike other coatings. UNIVOLEN High Chemical Resistant Coatings delivers significantly improved product performance and anti-corrosion resistance.

4) UNIVOLEN High Chemical Resistant Coating is formulated with a unique polymer designed and engineered with high functionality. This bridged aromatic backbone structure, when polymerized, forms up to 784 cross-links.

5) UNIVOLEN High Chemical Resistant Coating cross-links predominately through an ether (carbon-oxygen-carbon) linkage.

6) This eliminates high concentrations of hydroxyl groups (found in epoxies) and precludes formation of ester groups (found in vinyl esters) which are subject to hydrolysis and acid attack.

7) UNIVOLEN High Chemical Resistant Coating can be ambient cured or low temperature forced air cured depending on substrate and service conditions.

8) The Paint also provides chemical resistance to all mild acids and mild alkalis.

9) We can procure our range as per the requirement of our clients having special chemical resistance properties. Depending upon the surrounding environment, we design special grade of chemical resistant paint.

Durable Protection for Challenging Environments

Chemical Resistant Coatings shield industrial and commercial surfaces from corrosive chemicals, moisture, and mechanical wear. The epoxy or polyurethane formulation provides reliable defense for floors and processing areas exposed to harsh substances, significantly reducing maintenance costs over time. This solution is designed to offer long service life in demanding settings, making it a preferred choice for chemical plants and heavy-duty facilities.

Superior Coverage and Easy Application

Each coat of Chemical Resistant Coatings covers 68 m per litre, allowing efficient coverage of large areas. With a simple mixing ratio of 4:1 (base to hardener by volume) and a recommended two-coat application, it ensures optimal protection. The product forms a robust glossy layer that dries within 46 hours and fully cures in 2448 hours, minimizing downtime during installation.

Safety, Storage, and Versatile Colors

Post-curing, the coatings are non-toxic, making them safe for use in most industrial environments. Store the product in a cool, dry, and well-ventilated area to maintain a shelf life of 12 months. Available in standard and custom colors, the finish blends seamlessly with varied design requirements while upholding critical safety and performance standards.

FAQs of Chemical Resistant Coatings:

Q: How should surfaces be prepared before applying Chemical Resistant Coatings?

A: All surfaces must be clean, dry, and completely free of oil, dust, and contaminants before application to ensure optimal adhesion and durability.Q: What is the recommended number of coats and how should the product be mixed?

A: Apply two coats for best results, mixing the base and hardener at a 4:1 ratio by volume as specified. Mix thoroughly for a uniform, effective coating.Q: What is the coverage area per litre for each coat of Chemical Resistant Coatings?

A: Each coat covers an area of approximately 68 square meters per litre, depending on the substrates texture and porosity.Q: When can the coated surface be put back into service after application?

A: The surface will become dry-to-touch in 46 hours but requires 2448 hours for full curing before exposure to chemical or physical stress.Q: Where are Chemical Resistant Coatings typically used?

A: These coatings are ideal for industrial floors, processing areas, and chemical plantsanywhere surfaces require strong protection against corrosive chemicals and mechanical wear.Q: What benefits does this coating provide over standard paint?

A: Compared to standard paints, Chemical Resistant Coatings offer superior chemical resistance, high abrasion resistance, glossy finish, and long service life, significantly reducing the frequency and cost of maintenance.Q: Is the product safe to use and how should it be stored?

A: The product is non-toxic after curing. Store it in a cool, dry, and well-ventilated area to preserve its quality and shelf life, which is 12 months in the original sealed container.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+