Trusted company that deals in quality-made products

Exposed Steel Anti Corrosive Polyurethane Coating

550 INR

Product Details:

X

Exposed Steel Anti Corrosive Polyurethane Coating Price And Quantity

- 550 INR

- 100 Liter

Product Description

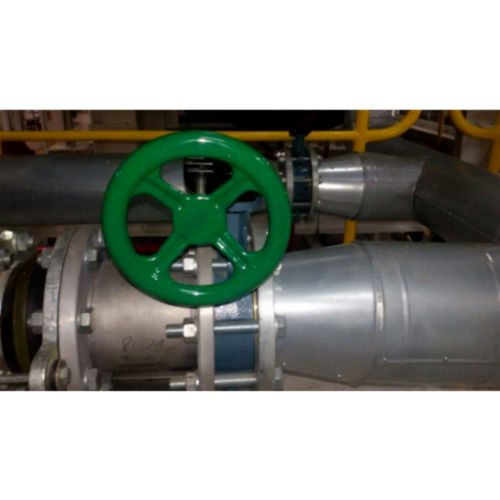

UNIVOLENANTICORROSIVE EP & PU COATING SYSTEM

These coatings used in marine weather or near high moisture area. These are mainly used to prevent the corrosion of metal and avoid the loss of the metal due to corrosion. The metal gets oxidized and loses its strength and property of supporting structure. This can be prevented with the help of suitable product. The product should be chosen after considering the main causes of the corrosion. If the corrosion is due to any other reason than moisture, then the chemical resistant coating should be used.

Superior Steel Protection

Specially formulated for the long-term protection of steel structures, this coating combines chemical resistance with anti-corrosive properties. Its strong adhesion ensures the film remains intact even in demanding industrial environments, prolonging the lifespan of steel assets and reducing maintenance costs.

Efficient Application and Coverage

Suitable for diverse application methodsspray, brush, or rollerthe coating delivers a smooth, glossy finish. With a recommended film thickness of 50-100 microns per coat and coverage of 8-10 m per litre, it is ideal for large surface areas. The product allows for easy recoating and maintains low VOC for a safer work environment.

FAQs of Exposed Steel Anti Corrosive Polyurethane Coating:

Q: How is the Exposed Steel Anti Corrosive Polyurethane Coating applied to steel surfaces?

A: The coating can be applied using a spray, brush, or roller. For best adhesion and finish, it is recommended to ensure the surface is clean and dry before application. Follow the recommended mixing ratio of Base:Hardener = 4:1 by volume.Q: What makes this coating highly resistant to chemicals and abrasion?

A: The polyurethane formulation provides robust resistance to oils, solvents, acids, and alkalis, making it suitable for industrial environments prone to chemical exposure. Additionally, excellent abrasion resistance helps maintain surface integrity over time.Q: When should recoating be performed for optimal protection?

A: For best results, a recoating interval of 8-12 hours is recommended between coats. Each coat should reach surface dryness within 1 hour, with full curing achieved after 7 days.Q: Where can this anti-corrosive coating be used?

A: This product is designed for steel structure protection, commonly utilized in industrial facilities, infrastructure projects, and maintenance of exposed metal frameworks.Q: What is the coverage area per litre and recommended film thickness?

A: Each litre of the coating covers approximately 8-10 square meters per coat, depending on the surface, with a recommended film thickness of 50-100 microns per application.Q: What are the main benefits of using this polyurethane coating?

A: Users benefit from excellent corrosion prevention, chemical and abrasion resistance, a smooth glossy finish, and low VOC emissions. The coating extends steel lifespan and minimizes frequent maintenance requirements.Q: How long does the product remain usable after mixing, and what is its shelf life?

A: Once mixed, the pot life of the product is 4-6 hours at 30C. The unopened product has a shelf life of 12 months when stored properly.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email