Heat Resistant High Temperature Coating

Product Details:

Heat Resistant High Temperature Coating Price And Quantity

- 100 Liter

- 1350 INR/Liter

Heat Resistant High Temperature Coating Trade Information

- 1 Liter Per Week

- 1 Week

Product Description

Our firm is instrumental in rendering a broad arrangement of Heat Resistant High Temperature Coating Paint Services. These are praised amongst our clients for its water based roof coating purposes. These are mainly utilized to shield from heating outside and keep it in a cool manner. Heat Resistant High Temperature Coating Paint Services are made with a silicon based materials which gives an amazing level of heat resistance and colourfastness. Demanded in the automotive and engineering industries.

Specification :

|

Application Method |

Brush |

|

Heat Resistant Coatings |

HEAT RESISTANT THERMAL INSULATION COATING |

|

Application Surface |

METAL, FIREBRICKS, WALLS |

|

Packaging Size |

20 LTR |

|

Finish |

Matt |

|

Brand |

UNIVOLEN |

|

Packaging Size |

20LTR |

|

Form Of Paint |

Liquid |

|

Paint Base Type |

Water Based Paint |

Unmatched Heat Resistance for Demanding Applications

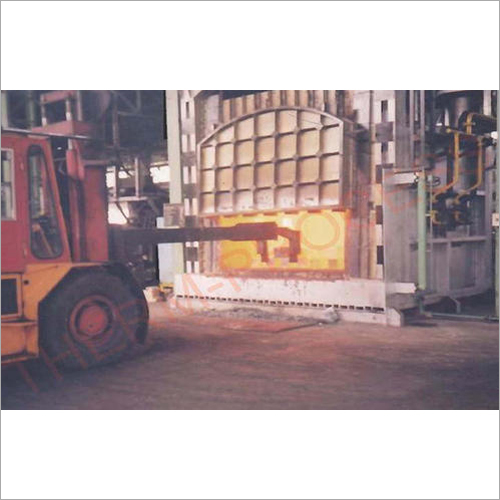

Engineered to withstand temperatures reaching 600C, our silicone resin-based coating provides robust protection in high-heat environments. It is the ideal solution for factories, foundries, and settings where machinery or structural metals endure extreme temperatures. The coatings strong adhesion and resilience extend the lifespan of steel and iron surfaces, reducing maintenance and replacement costs.

Versatile and Environmentally-Friendly Solution

Our coating not only offers superior heat protection but does so with low VOC content, contributing to a safer workspace. Its water-resistant properties further enhance durability, making it suitable for indoor and outdoor applications. The shelf life of 12 months gives users flexibility in storage and usage planning.

FAQs of Heat Resistant High Temperature Coating:

Q: How should the Heat Resistant High Temperature Coating be applied to metal surfaces?

A: The surface must be clean, dry, and free from oil or rust before application. Apply the coating evenly using a brush, spray, or roller, ensuring full coverage of the steel or iron substrate. Allow the coating to cure undisturbed for 24 hours for optimum performance.Q: What are the main benefits of using this high temperature coating on metal surfaces?

A: Key benefits include heat resistance up to 600C, protection from water and corrosion, and low VOC emissions, which create a safer work environment. It extends the service life of metal structures and equipment in industrial settings.Q: When is the coating fully cured and ready for high temperature exposure?

A: The coating requires a full 24 hours to achieve complete curing. After this period, the surface is ready to be exposed to high temperatures and harsh conditions.Q: Where can this coating be used for best results?

A: This product is best used on metal surfaces like steel and iron found in industries such as manufacturing, automotive, petrochemical, and power plants, where high heat resistance and durability are essential.Q: What is the proper process for storing the coating to maintain its shelf life?

A: To preserve the 12-month shelf life, store the product in a tightly sealed container in a cool, dry place away from direct sunlight and moisture. Avoid repeated opening to prevent contamination.Q: Is this coating suitable for both indoor and outdoor environments?

A: Yes, its water-resistant formulation allows for effective use indoors and outdoors, protecting metal surfaces from both heat and environmental factors.Q: What makes this product environmentally friendly compared to traditional coatings?

A: With its low VOC content, the coating reduces harmful emissions during application and curing, making it a safer and more environmentally-conscious choice for industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+