Anti Skid Epoxy Paint Coating Services

Product Details:

Anti Skid Epoxy Paint Coating Services Price And Quantity

- 875 INR/Liter

- 10 Liter

Anti Skid Epoxy Paint Coating Services Trade Information

- 100 Liter Per Month

- 7 Days

Product Description

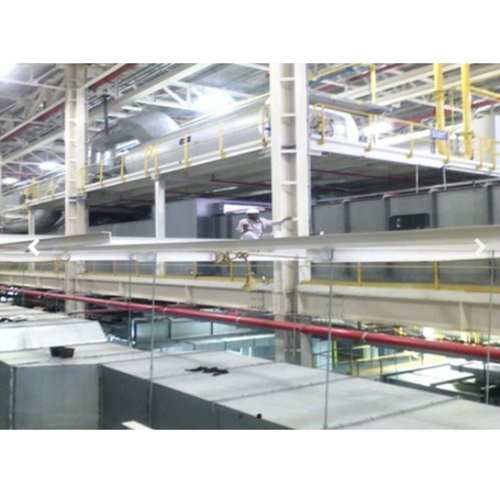

Anti Skid Epoxy Paint is widely acclaimed among our customers owing to its top notch quality and performance. It is ideally suitable for production areas, warehouses, workshops, goods in/out areas, plant rooms, among others. Anti Skid Epoxy Paint can also be used in any floor that is heavily trafficked by fork lift trucks, pallet trucks, cars and pedestrians. It is easy to apply and maintain. We are supplying Anti Skid Epoxy Paint in impermeable packaging that keeps the product safe during transportation.

APPLICATION:

Apply the coating immediately after mixing by roller. One or two coats can be applied. For best results apply two coats. Do not apply too generously otherwise the slip resistance will be compromised. Apply at a coverage rate of approximately 25 square meters per 4.5 litre pack. The second coat must be applied within 7 days. If this period is exceeded then lightly abrade the surface with carborundum papers to form a key for the second coat.

Comprehensive Safety Solutions for Industrial Environments

Our Anti Skid Epoxy Paint Coating Services address safety concerns across various sectors, including manufacturing units, parking lots, and warehousing facilities. The unique epoxy formulation delivers both durability and resistance to chemicals, making it an ideal choice for demanding industrial environments. The textured surface ensures slip prevention, even in busy or spill-prone areas, while the matte finish enhances visibility and cleanliness.

Customizable Application for Diverse Requirements

Whether you need a thin protective film or a thicker, highly resistant coat, our services offer flexible application methodsroller, brush, or spraytailored to your sites specifications. The coatings are available in a variety of colors and can be adjusted for thickness ranging from 300 to 500 microns. This ensures both aesthetic appeal and functionality, adapting to each clients unique preferences and operational demands.

FAQs of Anti Skid Epoxy Paint Coating Services:

Q: How is the Anti Skid Epoxy Paint applied to industrial floors and walkways?

A: The coating is applied using a roller, brush, or spray technique, depending on the surface and area size. These methods ensure optimal coverage and adhesion to concrete substrates in industrial settings.Q: What areas can benefit from Anti Skid Epoxy Paint Coating Services?

A: Industrial floors, warehouses, manufacturing units, walkways, and parking lots all benefit from anti skid epoxy coatings due to their slip-resistant surface and excellent durability.Q: When can the coated surface be used after application?

A: The anti skid epoxy paint coating requires a drying time of 6-8 hours. After this period, the surface can be safely used for regular operations, and full curing ensures maximum performance and longevity.Q: Where should Anti Skid Epoxy Paint be utilized for maximum benefit?

A: It is ideal for areas that experience frequent foot or vehicular traffic, potential spills, or exposure to chemicals, such as factory floors, warehouse interiors, walkways, and parking areas.Q: What is the process for customizing the thickness of the coating?

A: The thickness of the epoxy coating, typically between 300-500 microns, can be tailored to client requirements during the application process. Our technicians assess site needs and adjust material amounts to provide optimal protection.Q: How does this epoxy paint enhance safety and maintenance?

A: The anti skid feature reduces accidents arising from slips, while the surfaces chemical and wear resistance simplifies cleaning and minimizes maintenance needs, ensuring a long-lasting finish.Q: What are the long-term benefits of using Anti Skid Epoxy Paint Coating Services?

A: This coating delivers a resilient, wear-resistant, and easy-to-maintain surface that retains its safety and aesthetic properties over time. It also offers excellent protection against oils, chemicals, and solvents, lowering replacement costs and improving operational safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+